Index CNC Dowel Insertion

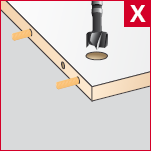

CNC (Computer Numeric Control) drill and dowel inserting machines for fully automatic bore, glue and dowel insertion. Use the Index CNC to provide automated precision control of your production process. The Index series of drill, glue and dowel machining centers provides a compact frame with speed, accuracy, flexibility and quality.

Index Logic 70-130

- Universal CNC controlled drilling and dowel inserting machine

- Glue shot monitoring via GIC (Glue Injection Control)

- Closed gluing system

- Suitable for panel and solid wood processing

- Optional additional horizontal and vertical drilling spindles

- Relieves CNC machining centers workload

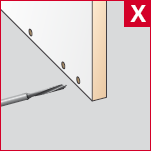

- Optimal complement to nesting machines due to it's ability to drill on the edges and insert dowels

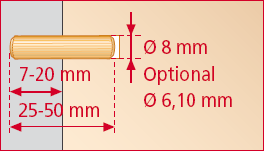

The Logic 70 has a working width of 700mm (27-1/2") with two zones and two steel side referencing stops. There are four pneumatic clamping cylinders. Max work piece thickness is 80mm.

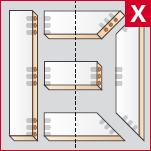

The Logic 130 has a working width of 1300mm (51-1/8"). It is a truly independent 4 zone machine with 4 steel referencing stops. The center stop comes standard with a pneumatic switch to give quick access to the entire 1300mm working width. There are standard eight pneumatic clamping cylinders for work piece thickness max 80mm, work piece length min. 70mm.

Standard features:

Optional:

Optional:

Request Quote for Gannomat Index Logic 70

Request Quote for Gannomat Index Logic 130

Index Trend 130-330

The Index Trend is Gannomat's second CNC drilling, gluing and dowel insertion machine. The Index Trend offers larger frame sizes (1300mm – 3300mm) and additional options not available with the Index Logic. These options can be added individually according to the customer's production.

Standard features:

Optional:

Optional:

Request Quote for Gannomat Index Trend 130-330

Index Pro 130-330

The Pro provides the most options in the Index series of CNC dowel insertion machines which makes it an excellent choice for dowel insertion, machining for RTA fittings, drawer parts, frames, confirmats and all production requiring multiple boring patterns and hole sizes. The Index Pro also provides routing and grooving options.

The Pro has the added advantage of incorporating horizontal and vertical drilling units with three to seven individually programmable boring spindles each. This provides your production the most flexibility in a CNC dowel insertion machine.